LABORATORY SERVICES

Care and precision for all laboratory requirements

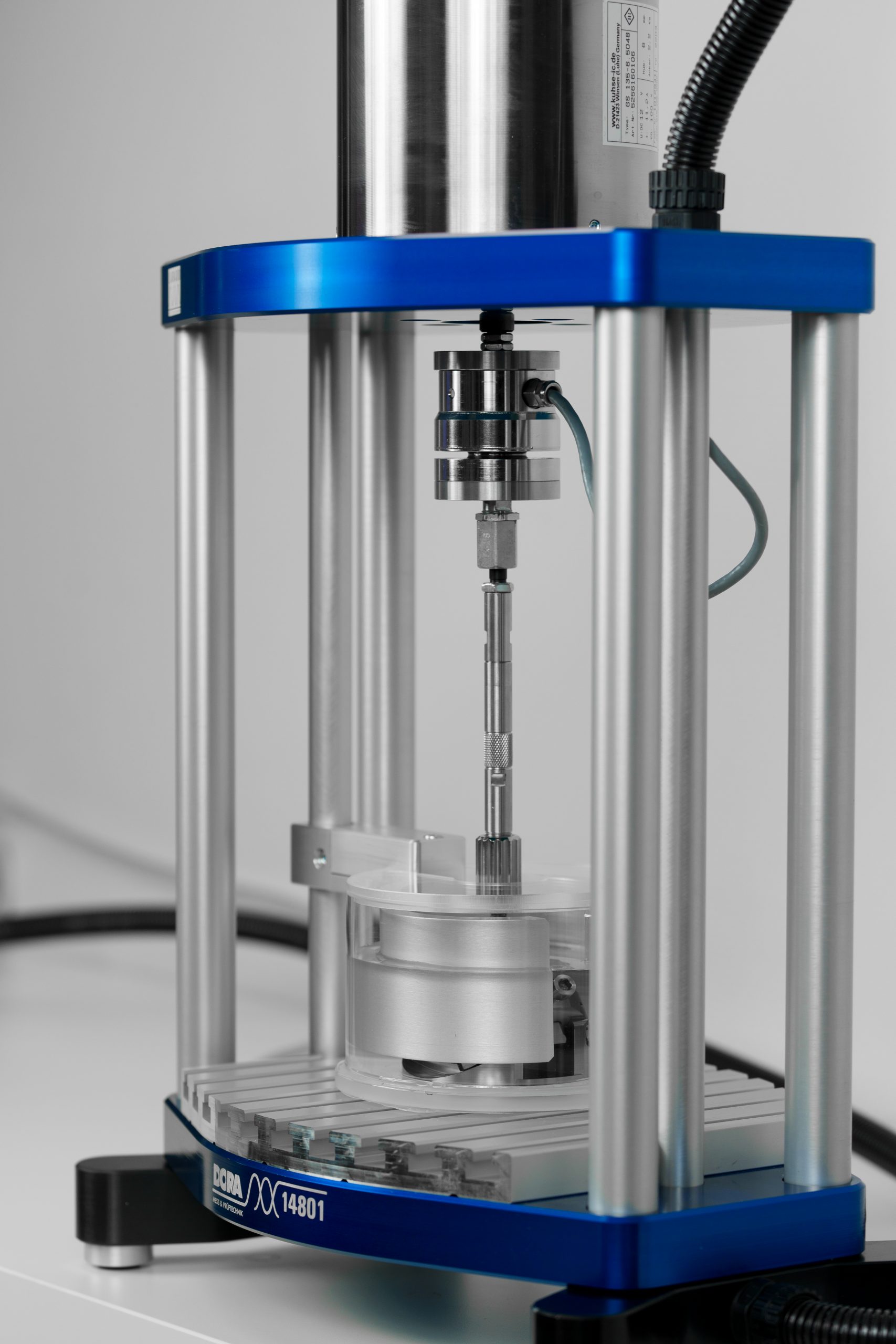

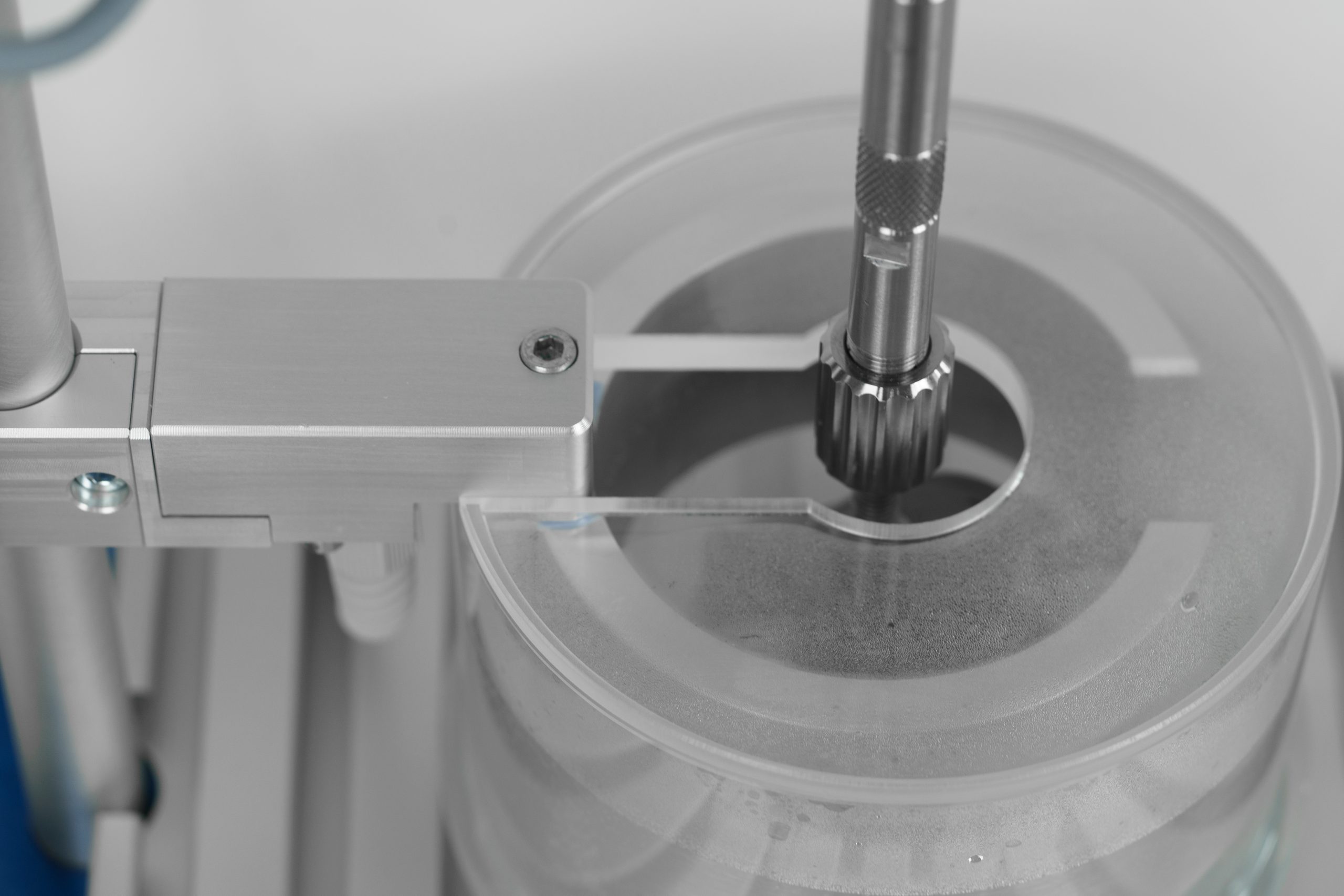

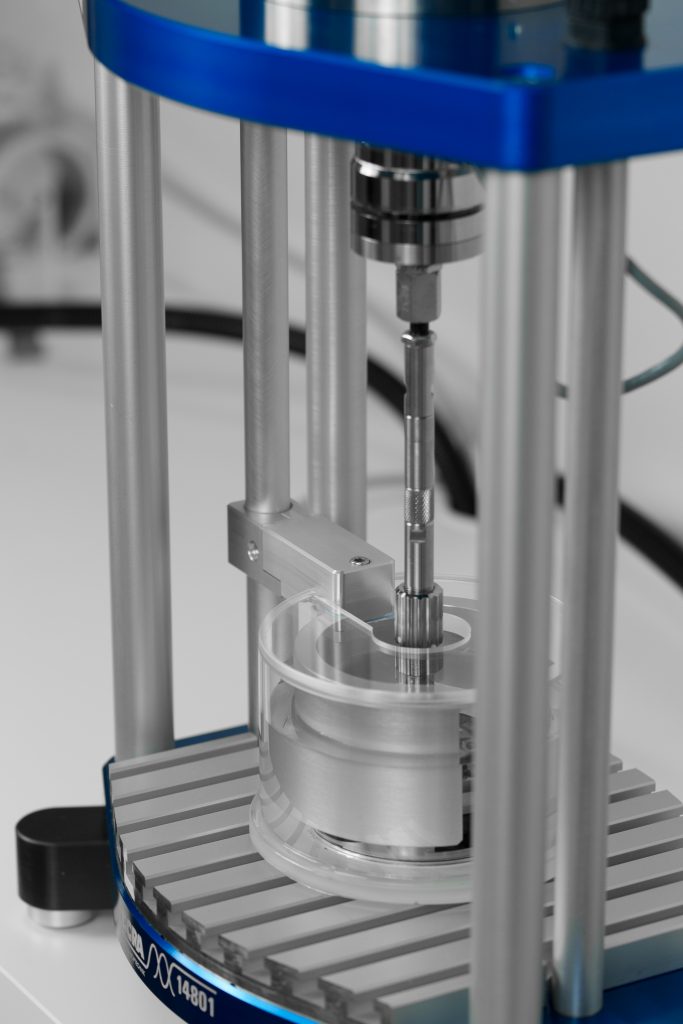

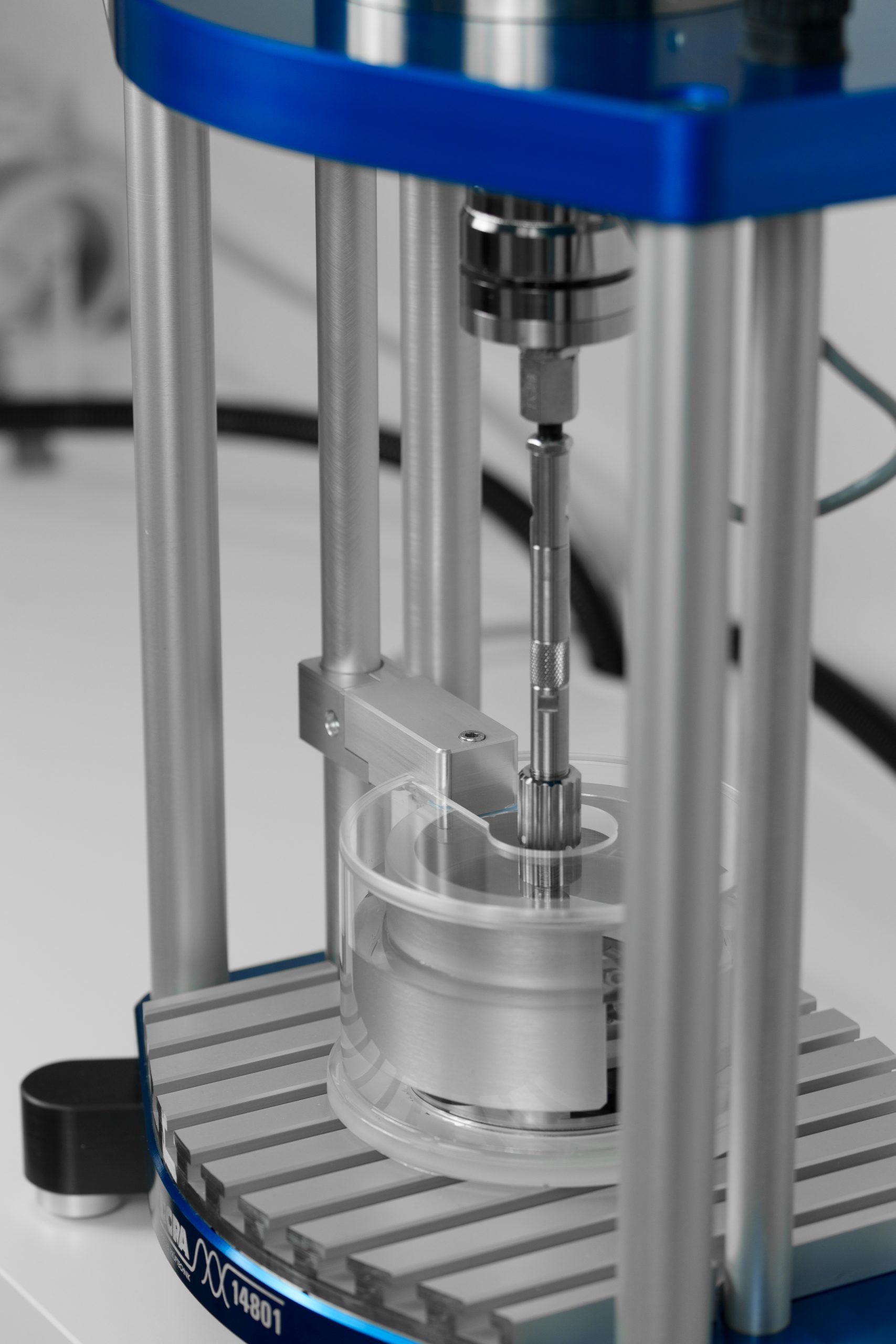

Specializing in implant abutment testing with our patented and proven DORA devices, we offer you comprehensive and quality-assured product analyses in accordance with DIN EN ISO 14801 standards.

Implant-abutment connection testing

according to DIN ISO 14801 (dry 15Hz)

DIN ISO 14801 is a standard that specifies requirements for dental implants and their components. Among other things, it specifies test methods for the mechanical strength of implants.

For a test in accordance with DIN ISO 14801, you provide us with at least 15 test specimens (ideally 18 test specimens). We prepare these for testing with the highest precision and the latest technology, then we start the tests on our DORA machines under dry conditions (15Hz / 5,000,000 cycles / room temperature). Once the tests have been completed, you will receive a detailed report that meets the requirements of official bodies.

Please contact us for further information.

Implant-abutment connection testing

according to DIN ISA 14801 (wet 2Hz)

DIN ISO 14801 is a standard that specifies requirements for dental implants and their components. Among other things, it specifies test methods for the mechanical strength of implants.

For a test in accordance with DIN ISO 14801, you provide us with at least 15 test specimens (ideally 18 test specimens). We prepare these for testing with the highest precision and the latest technology, then we start the tests on our DORA machines under wet conditions (2Hz / 2,000,000 cycles / 37°C NaCl solution). Once the tests have been completed, you will receive a detailed report that meets the requirements of official bodies.

Please contact us for further information.

Surveys

ReEngineering

We are happy to support you with your measurement or reengineering of dental implants to ensure that they meet your requirements.

For reengineering, we need at least 10 parts in 3 different batches from you. This concerns the implant, abutment and screw. These are then measured using various measuring techniques (CT / optical / tactile) and a report with suitable technical drawings is then created. STP files can be obtained on request.

Please contact us for further information.

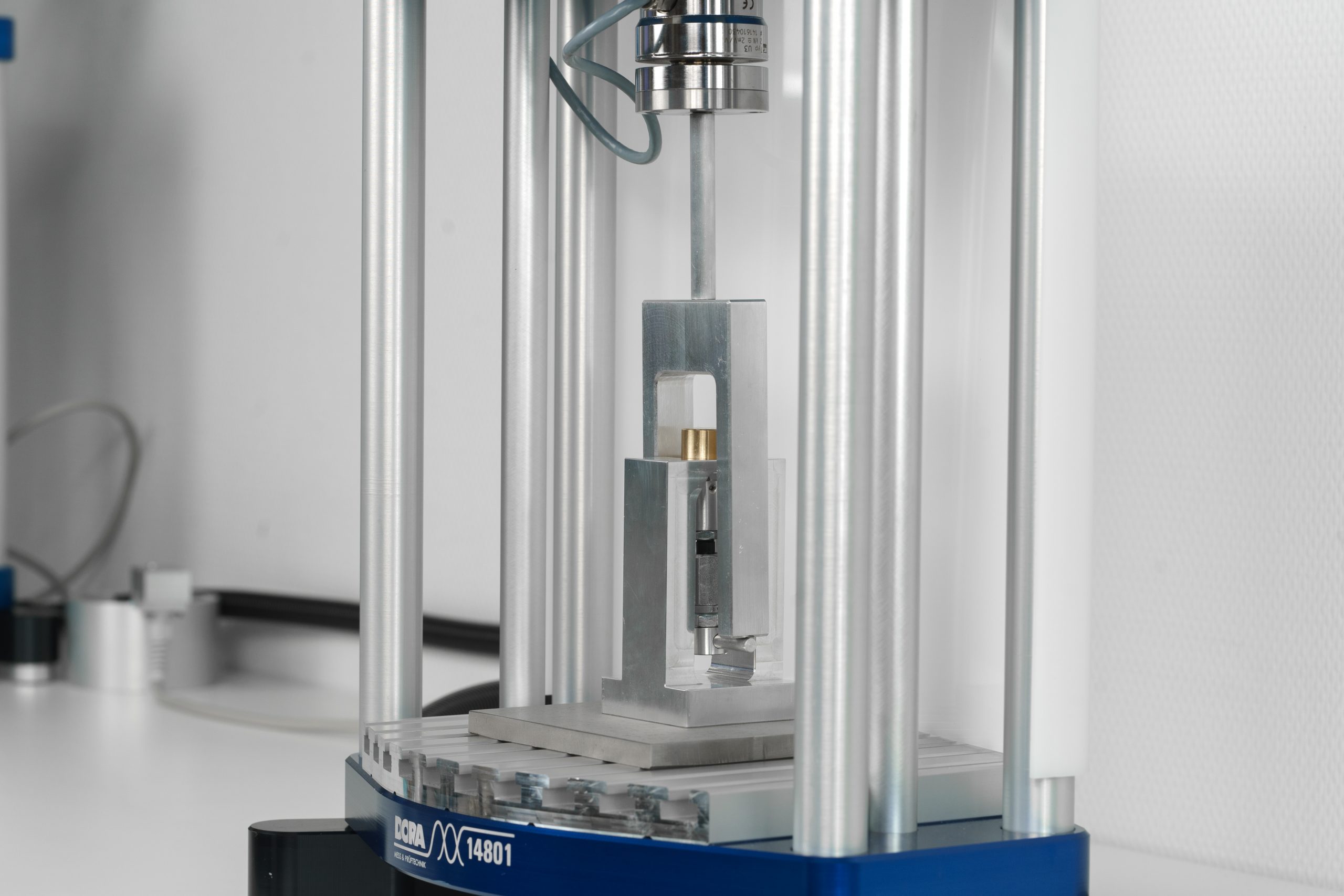

Shear-off comparisons

- Specially designed testing system for dental implantology

- Developed for product monitoring, product development and quality assurance in accordance with DIN EN ISO 14801.

High energy efficiency

- Very low power requirement of approx. 120 watts per test station.

- A 230-volt connection is sufficient.

No external connections required

- No connections to compressed air or hydraulic systems necessary.

High-precision sensors

- High-precision force sensor designed for fatigue strength.

- Displacement sensor with micrometer resolution.

Simple network connection

- Connection via LAN.

Please contact us for further information.

Train tests

- Central monitoring and control unit with a modular overall system configuration of one to eight individual test stations.

Our development engineers have responded with fundamental innovations, particularly with regard to the flexibility of the system size.

Until now, single-station testing systems were the rule,

the modular design of the DORA 14801 test system allows parallel operation of up to eight individual test stations using just one central control unit - the DORA CONTROL.

Operate up to 8x 14801 DORA testing machines simultaneously with DORA Control

Please contact us for further information.